Coating for PLA substrates

PLA coating is a Water-borne coating that provides excellent printing performance on overlay/card-making materials surface and it’s suitable for PLA offset printing.This product can provide excellent printing adaptability after coating on PLA substrates. This product has excellent ink adhesion, no deformation after heat lamination and superior aging resistance performance.

❏Characteristics:

1.Suitable for offset printing on PLA substrates.

2.No solvent or gas discharged during use.

3.Excellent adhesion&Excellent aging and water resistance performance.

4.Suitable for Silkscreen.

❏Technical Spec:

Item | Parameters |

Appearance | Milky Cream Liquid |

Solid Content | ≥20% |

Viscosity(25℃) | 600~700mPa·s |

Volatile matter | Water |

Applicable technology | Silk-screen Ink |

Recommended Silk Screen Mesh | 200~350 |

Storage | Sealed、Moisture Proof Temp:5~30℃ |

❏Recommended process:

1.Coated on the surface of the substrate,the coating amount is 6~7g/m2 after drying.

2.Printing after coating and drying.

3.Lamination use traditional card printing process after printing. During lamination, the surface of the printed content should be covered with coated overlay. Recommended lamination process shown as follows:

Laminating Condition | Heat Laminating | Cool Laminating |

Temp(℃) | 120~150 | ≤25 |

Time(min) | 15~20 | 15~20 |

Pressure(MPa) | 5~10 | 5~10 |

❏Packing:

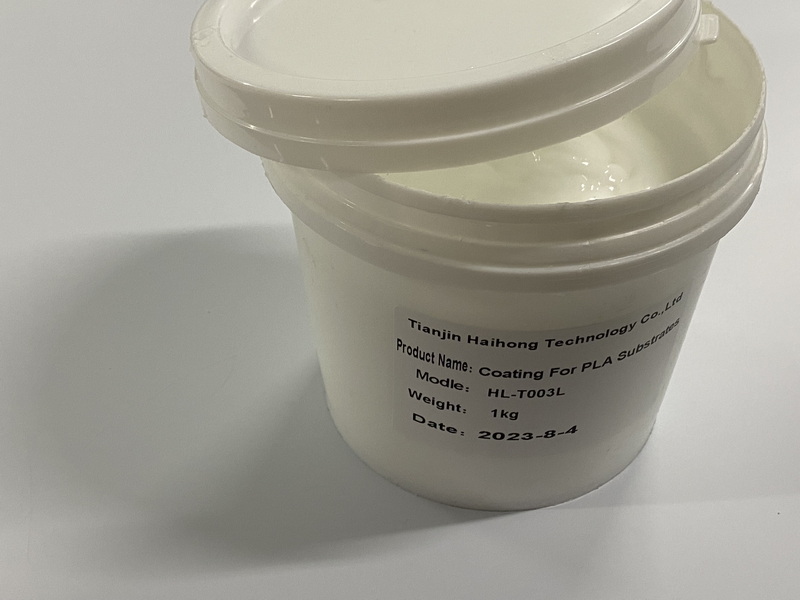

Sample packing:1kg/can

Product packing:3kg/can

❏Notes:

Do not mix with other kinds of coatings;

The printing coating shall not be diluted with distilled water;

Avoid oil stains during coating;

Silkscreen printing and coating continuously, prevent peeling and curing;

After the silkscreen is coated with glue, the silkscreen should be washed with the appropriate wash in time.

全国服务热线

全国服务热线